Traction Sheave Catalogue

How does the drawings library work?

Sorting by manufacturer

I. Choose the manufacturer.

II. Choose one item from the list of available components.

III. Choose the drive.

The drive form is displayed once you have specified all three of these items.

You can now fill out the drive form on your computer and print it.

Sorting by drive type

This sorting mode is for cases where the type of drive required is known.

The menu is structured as follows: Drive type – component – manufacturer/brand.

If there is a variety of components available for the same drive, then several drive types will appear in the drop drown menu.

Example:

Seeking: 11BT

Result: 11BT-Traction sheave-OTIS, 11BT-Traction sheave rim-OTIS

The drive form is displayed once all specifications have been entered. You can now fill out the form on your computer and print it.

Sorting by screw space

In this sorting mode, only traction sheave rims are displayed in the tool bar.

The list of traction sheave rims is sorted as follows:

screw space – number of screws – thread – manufacturer/brand

Should the three first values above be known, finding your required rim(s) is easy even if the manufacturer or drive type are unkown.

Assume your traction sheave rim measures as follows:

Screw space a: 73 mm

Number of screws: 12

Thread: M16

The search criteria entered would be as follows: 73-12xM16

Results: 73-12xM16-ZF

Meaning, you probably require this rim:

Make ZF for drive RME210/WSP2100

The drive form is displayed once all specifications have been entered. You can now fill out the form on your computer and print it.

How to fill out the form

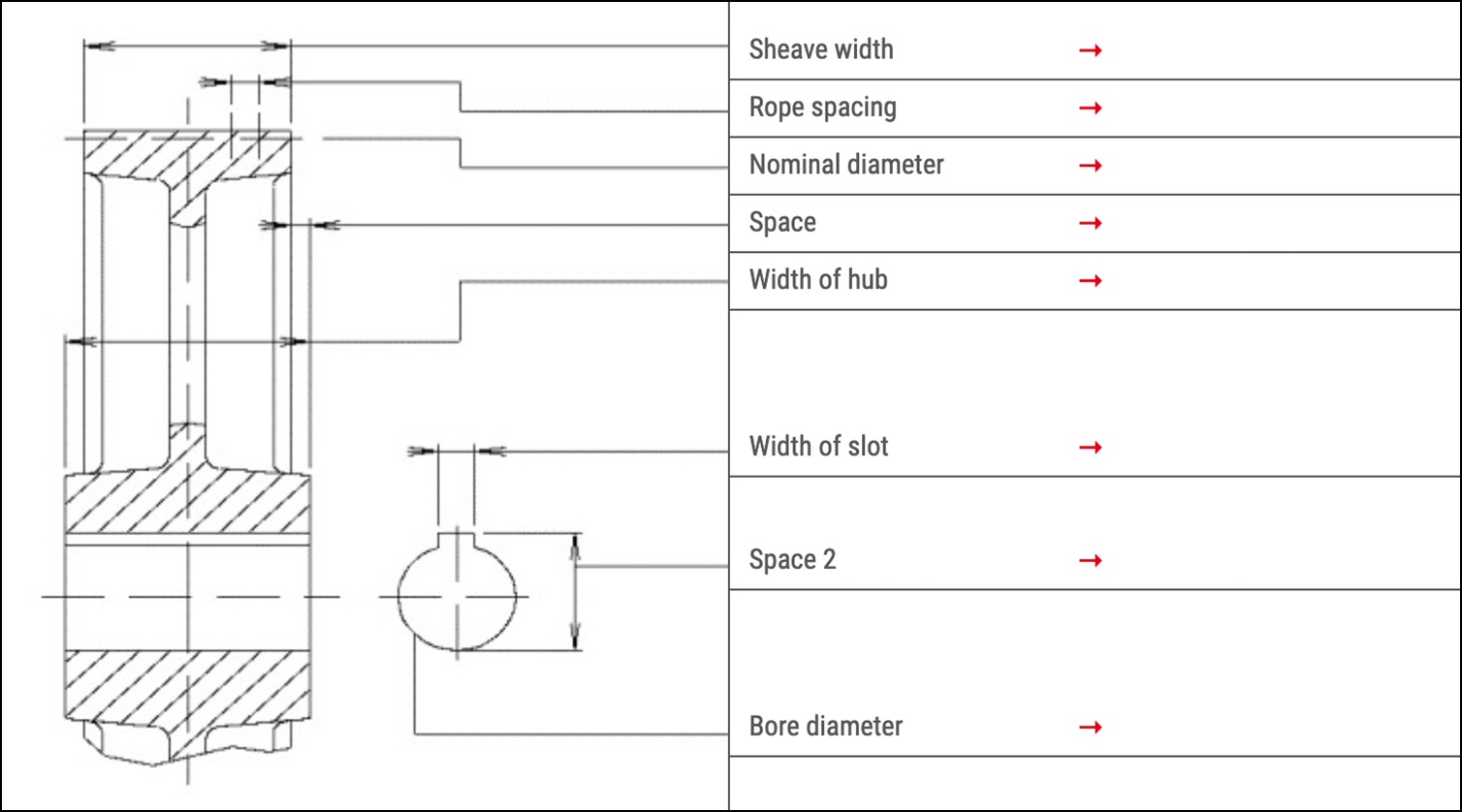

The components are shown on a standardized form. The structure of this form is always identical.

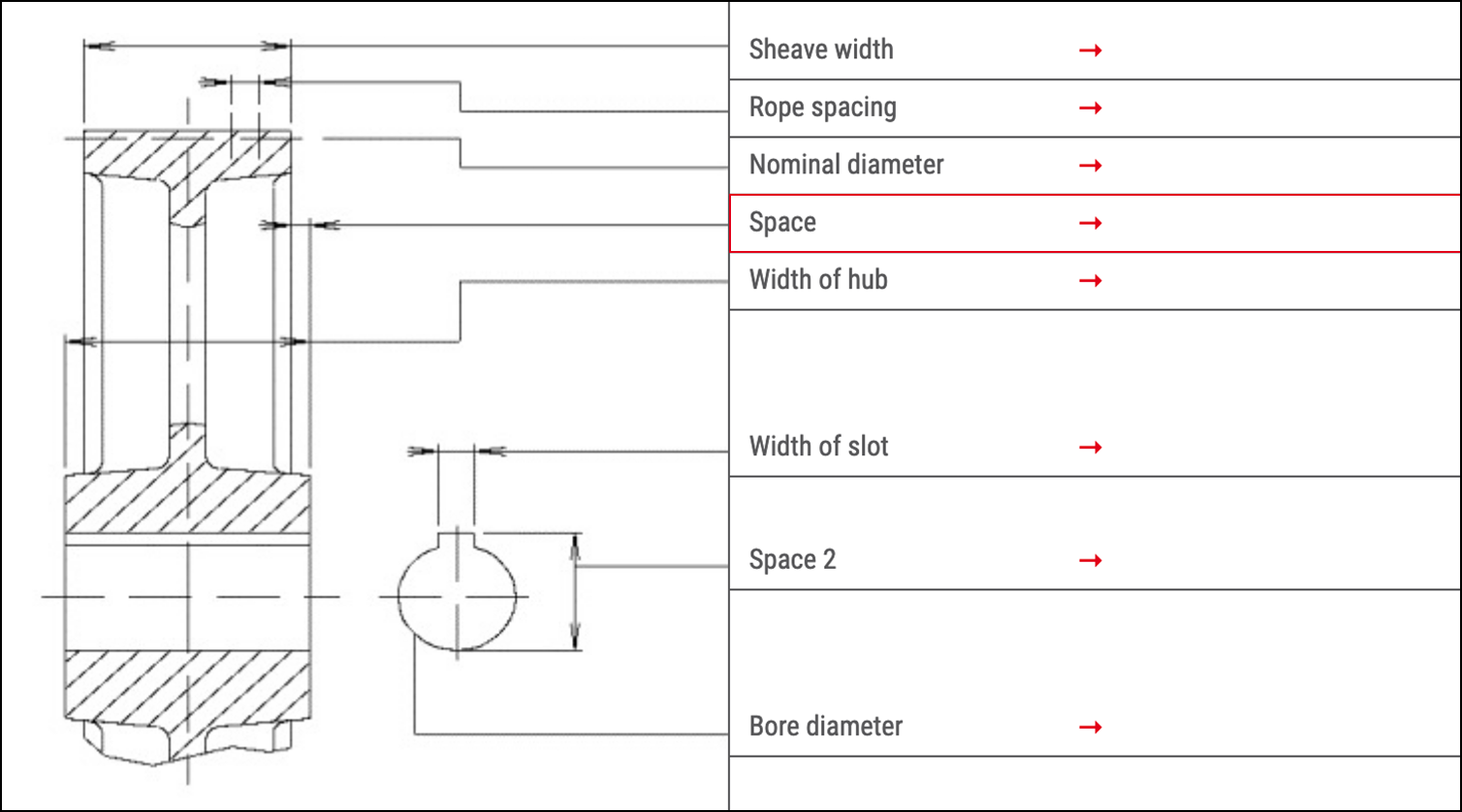

Drawing and geometric data

Fill in the fields with the requested information; should some of the fields already contain information, check the data for errors.

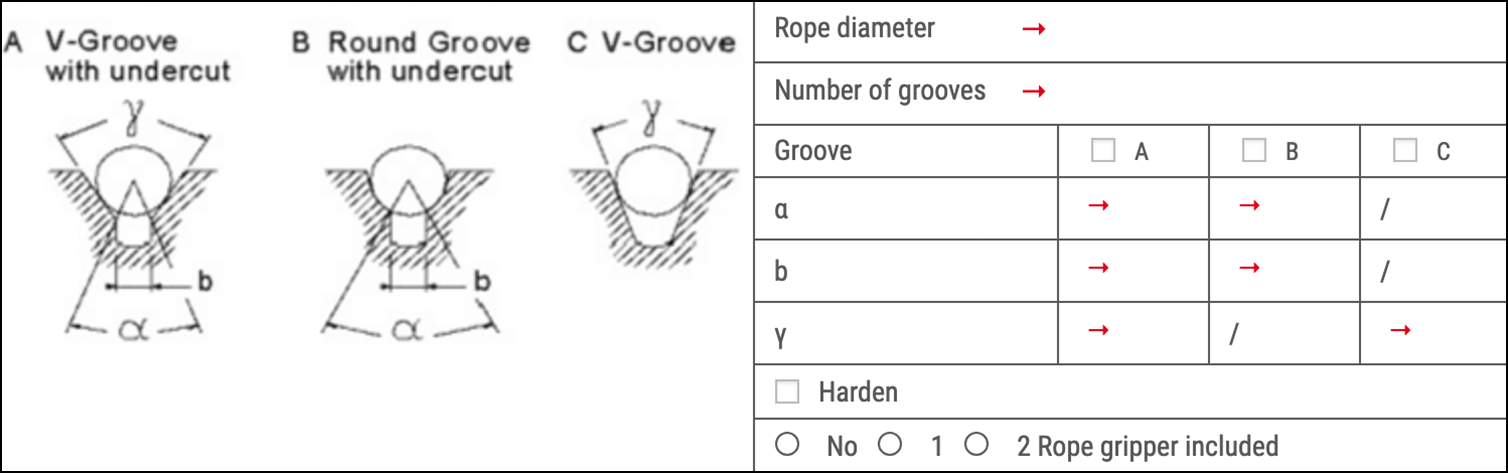

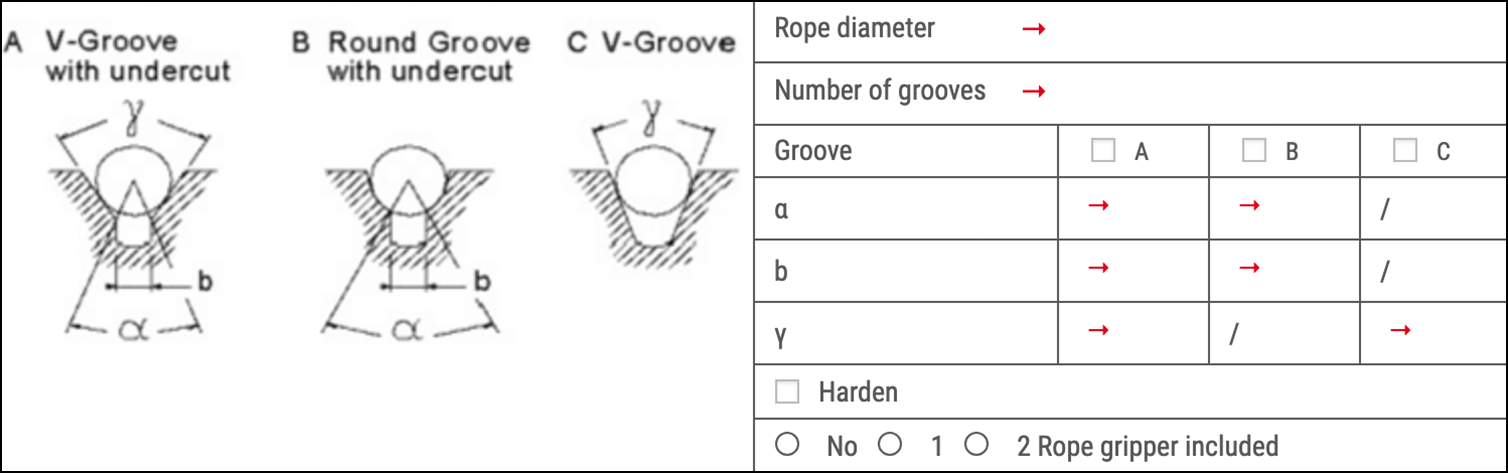

Groove specifications

Fill in the fields with the requested information. Depending on the groove design, you may need to include additional specifications (see elevator manual). Please note that you can enter varying degrees of hardness. We are happy to supply one or two rope clamps upon request.

Customer details

Enter your company name and contact information. Entering a project name is optional, but recommended for your convenience.

For all drawings:

The right hand side of the traction sheave always faces the drive. It is referred to as the “Inner” measurement. “Outer” measurements refer to the away side (as seen from the drive). All measurements are always specified in [mm].

One Special Feature: Space measurement

Traction sheaves come in many forms, for example with or without hubs. Hub width can be smaller, greater or equal to the rim width. For the sake of simplification, this detail is not included in the forms. Even if this results in the original traction sheave not being identical to the traction sheave drawn on the form, these variations can be specified quite precisely through use of Space measurement.

Please follow the applicable conventions as shown in the examples below:

Example 1:

Space entered on form as 0.

Example 2:

Space entered on form with a preceding “+” sign.

Example 3:

Space entered on form with a preceding “-” sign.

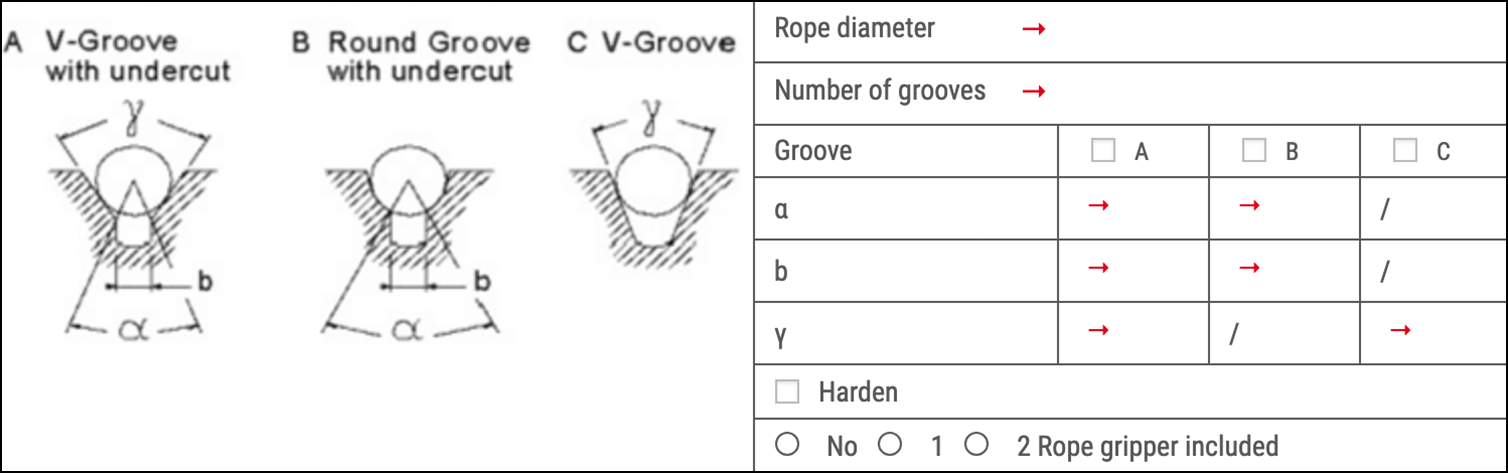

Which groove design specifications are required?

Please always include the groove design and associated values in the form. These measurements are so specific to the individual plant and usually found in the elevator manual. Please ensure the documents from which you obtained these specification is still up to date!

Depending on the groove design, a variety of data is required for proper measurement:

The number of screws determine value a for the screw space. Please insert value a into the following formula:

Arc diameter = Screw space a* factor

A: V-groove with undercut:

Please state the correct values for:

| Name | Symbol | Unit |

| V-angle gamma | Y | [Degrees] |

| Undercut angle alpha | α | [Degrees] |

| Lower cutting width | b | [mm] |

B: Round groove with undercut:

Please state correct values for:

| Name | Symbol | Unit |

| Undercut angle alpha | α | [Degrees] |

| Lower cutting width | b | [mm] |

C: V-groove:

Please state correct values for:

| Name | Symbol | Unit |

| V-angle gamma | Y | [Degrees] |

Please note: Without these specifications it is not possible to manufacture a traction sheave.

Traction sheaves can be hardened upon request. Please click “harden” on the form if you want this service included in our offer.

What to do in case the manufacturer or the drive type are unknown?

Please select "traction sheaves general" or "traction sheave rims general" from the first menu. You should be able to obtain the information you need by continuing to select items from the menu based on the knowledge you have available about the traction sheave/traction sheave rim you are seeking to replace.

What to do in case I didn't find a suitable component?

We will be glad to help. Our prototype division will create a suitable model out of polystyrene. This procedure can be used to make almost any traction sheave or rope pulley variant at an economic cost. To carry out the procedure accurately, we require a technical drawing suitable for production engineering purposes or a sample of the traction sheave or rope pulley.

Useful Information

Specifying a traction sheave rim

Traction sheave rims are connected to the hub using fitting screws. Such rims are usually easy to specify if the following data is available:

- the size of screw space a

- the number of screws used

- the size of these screws

How to determine screw space a:

Measure from the middle of a screw to the middle of the adjacent screw in a straight line (a) or remove both screws and measure from the edge of one drill hole to the edge of the other drill hole in a straight line (space b).

How to dermine the thread:

| Thread | M10 | M12 | M14 | M16 | M18 | M20 |

| Width across flats old/new | 17 / 16 | 19 / 18 | 22 / 21 | 24 / 24 | 27 / 27 | 30 / 30 |

How to determine the arc diameter?

The arc diameter can be determined with the help of the screw space.

The screw space can be measured using one of two methods:

1. Measure from the middle of a screw to the middle of the adjacent screw in a straight line (space a).

2. Remove both screws and measure from the edge of one drill hole to the edge of the other drill hole in a straight line (space b).

Then, you can determine the arc diameter. Depending on the number of screws use the following formula and enter factor you determined in step one (either through method a or b):

Arc diameter = Screw space a* factor

The factor value of a depends on the number of screws, as specified in the table below:

| Number of fastening screws |

Factor |

| 4 | 1,414 |

| 5 | 1,701 |

| 6 | 2 |

| 8 | 2,613 |

| 10 | 3,236 |

Example:

Screw space a is 200 mm

Number of screws is 5

Then your arc diameter is = 200 mm * 1,701 = 340 mm

How to determine rope spacing?

The most precise measurement of rope spacing is obtained by measuring over all the ropes.

| Rope spacing is = | distance from first to last rope (No. of rope spaces) |

| No. of rope spaces is: | number of grooves -1 / Example: 6 - 1 = 5 |

| Example | |

| No. of grooves: | 6 |

| Distance from first to last rope is: | 100 |

| Rope space is: | distance from first to last rope No. of rope spaces |

| Equals: | 100 mm 5 |

| Result: | 20 mm |

Order & Delivery

How can I place an order?

How long will delivery take?

After obtaining your order we will send you an order confirmation by e-mail. Items in stock will be marked accordingly in the order confirmation. Should an item be out of stock, the next possible/expected delivery date will be indicated. The delivery date (indicated as a calendar week) for the shipment of your full order is stated in the upper right part of the order confirmation.

When will my order be delivered?

Your order will be summarized into one single delivery and be shipped as soon all items are in stock.

How can I obtain partial delivery in advance?

Should your order contain items in stock and items scheduled for a later delivery, we can ship the available parts of your order upon request. Please note that we will charge separate shipping costs for each of the deliveries. In order to request two partial deliveries, contact our customer service team by phone (+49 (0)221 53 99 58 10) and hold the number on your order confirmation for reference.

How will my order be shipped?

Should you make no deviating requests delivery will be carried by our main shipping company (currently: DB Schenker or UPS Standard). Handling usually takes about two to four business days. Shipping costs depend on the amounts ordered, their freight weight and their value. Costs will usually be included with our offer, but be determined in the order confirmation at latest. Express deliveries are available upon request. Don’t hesitate to contact us, we’re happy to inform you about all options available and their associated costs.

Shipping and Delivery Damages

What should I do if products and/or packaging were damaged during shipping?

Should it come to your attention that the packaging was damaged, please ensure to unwrap and examine the products while the delivery driver is still present. Should the products not be in perfect condition, please refuse to accept the package. If you can, take pictures of the damage incurred and include them in an e-mail to informing us delivery was refused.

Return / Return Shipments

What is the process for return shipments?

For items returned out of your own volition (e.g. not because the products were faulty or due to some other reason caused on our end), please use our return form. Costs for return shipments are to be covered by the customer. Please ensure to apply sufficient postage or to charge the delivery to your account when submitting the delivery.

What happens once the items have been returned?

Rudolf Fuka GmbH offers two solutions:

After the items and the return form have been sent to us at your cost, we will examine whether they are complete and intact. If we can confirm both criteria are met, we will include the products in our special warehouse for „Existing Inventory“. This stock is considered for all orders placed with us. Should the item returned be sold otherwise, you will obtain credit over the original product value excluding costs for packaging, shipping and an administration fee of 3% of the original invoice. Should the item not be sold within two calendar years after being placed in stock, you will obtain notice over the professional disposal of your product.

We reserve the right to refuse acceptance of return shipments without a correct return form or similar document. In addition, we preclude accepting any charges for return shipments. The same applies to any additional costs, such as tariffs or other fees which will not be incurred by us.

The process specified above does not equal a guarantee for reimbursement.

Which products are excluded from the return policy?

Electronic parts (e.g. magnets) or components that are no longer is as-delivered conditions are excluded. As a rule, parts whose lack of defects cannot be verified without significant technical inspection efforts are excluded from the return policy as well.

Return rights expire for all items once they are utilized.

Items which were commissioned and/or which we produced or procured for you in non-commercial amounts are also excluded from our return policy.